5 Things You May Not Know About Micro

News

- We were founded in 1944 by a family of German toolmakers.

- Equipment for the James Webb Space Telescope was made at the Micro facility.

- Micro machines components as large as 10' x 8' and as small as .030" in diameter.

- We have one of the largest 8,000 hour apprenticeship programs in New York!

- 95% of our manufacturing is done in-house.

Micro Instrument Corp featured in the "Rochester Business Journal"

News

In January, Micro Instrument Corp was featured as one of Rochester's top manufacturing companies that supports employees who enroll in the "New York State Apprenticeship Program" for advanced manufacturing. Currently, there are over 602 job openings in advanced manufacturing each year and roughly 43 percent are being filled with local, newly trained workers. Micro instrument Corp is proud to support the local Rochester workforce by being a large proponent to this program. Pick up a copy of the January 12th edition of the RBJ and read more about some of the great things happening in the manufacturing industry and how Micro is embracing the future of advanced manufacturing! You can also access the full version of the electronic article below.

https://www.microinst.com/cmsb/uploads/micro-instrument-corp-rbj-article.pdf

Micro Inspires Future Professionals

News

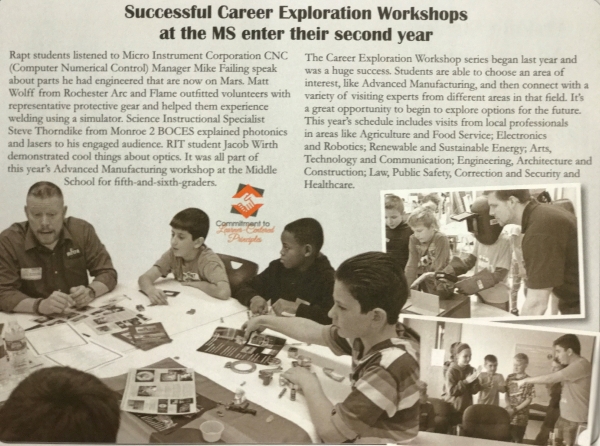

Rapt students listened to Micro Instrument Corporation CNC Manager Mike Failing speak about parts he had engineered that are now on Mars. It was part of this year's Advanced Manufacturing workshop at the Middle School for fifth-and-sixth-graders. The Career Exploration Workshop series began last year and was a huge success. Students are able to choose an area of interest, like Advanced Manufacturing, and then connect with a variety of visiting experts from different areas in that field. It's a great opportunity to begin to explore options for the future.

Micro continues to support Manufacturing education with class tours and events like this one. Micro also supports several vocational open-houses to encourage careers in manufacturing like those offered through our well respected apprenticeship programs.

New Haas VF9

News

In September 2016 Micro added a brand new Haas VF9 CNC machine to our facility. With it we can cut pieces up to 84" long.

Vertical Machining Center; 84" x 40" x 30" (2134 x 1016 x 762 mm), 40 taper, 30 hp (22.4 kW) vector drive, 8100 rpm, inline direct-drive, 24+1 side-mount tool changer, 600 ipm (15.2 m/min) rapids, automatic chip auger, programmable coolant nozzle, color remote jog handle, power-failure detection module, 1 GB program memory, 15" color LCD monitor, USB port, memory lock keyswitch, rigid tapping and 95-gallon (360 liter) flood coolant system.